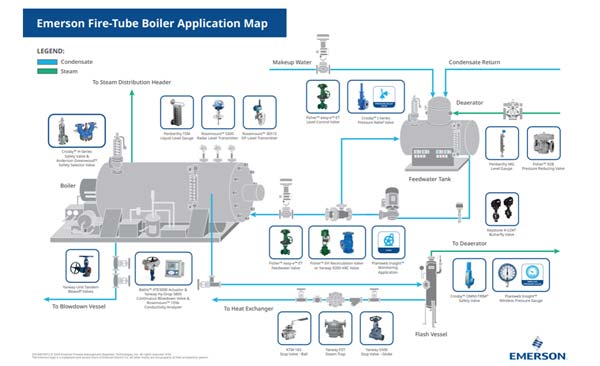

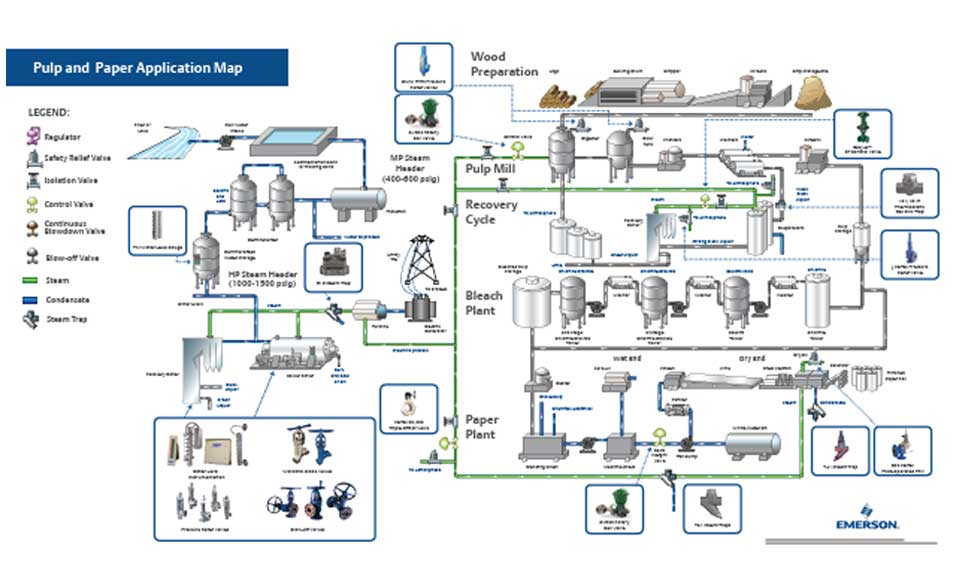

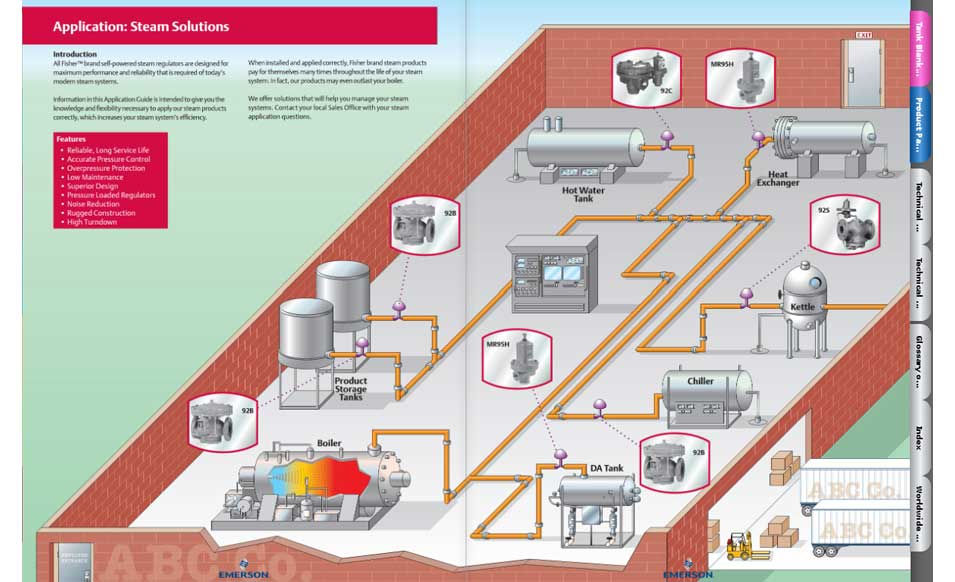

Emerson’s measurement products are highly valued in steam applications due to their precision, durability, and integration capabilities. Designed to withstand the demanding conditions of high-pressure and high-temperature steam systems, Emerson instruments—such as the Rosemount 8800 Vortex and 3051 Annubar—offer

accurate and stable flow, pressure, and temperature measurements. These devices often feature

multivariable capabilities, allowing for real-time mass and energy flow calculations, which are essential for optimizing steam usage and improving energy efficiency.

Emerson’s solutions are also known for their

robust construction, minimal maintenance requirements, and seamless integration with digital control systems, enabling predictive diagnostics and enhanced process visibility. This combination of performance, reliability, and smart technology makes Emerson a trusted choice for steam measurement in power generation, chemical processing, and industrial utilities.

Vortex Flow Meters

The Rosemount 8800 Series Vortex Flow Meters

The Rosemount 8800 Series Vortex Flow Meters are highly regarded for steam applications due to their robust design, accuracy, and reliability in harsh conditions. One of their standout features is the

non-wetted sensor design, which eliminates potential leak points and reduces maintenance needs—critical in high-pressure steam environments. These meters also offer

excellent vibration immunity and

stable measurement performance, even in fluctuating flow conditions typical of steam systems. Additionally, the integrated temperature and pressure compensation capabilities ensure

precise mass flow measurement, which is essential for energy management and efficiency in steam applications. Their ease of installation and minimal straight pipe requirements further enhance their suitability for compact or retrofit steam systems.

Learn More: Rosemount 8800 Flanged Vortex Flow Meter

Annubar Flow Meters

The Rosemount 3051 Annubar

Flow Meter is an excellent choice for steam applications due to its ability to deliver accurate, reliable, and cost-effective flow measurement in high-temperature and high-pressure environments. Utilizing

averaging pitot tube technology, the 3051 Annubar measures differential pressure across multiple sensing ports, providing a more representative and stable flow profile—ideal for the turbulent nature of steam. Its

integrated multivariable transmitter can simultaneously measure differential pressure, static pressure, and temperature, enabling

real-time mass and energy flow calculations without the need for additional instrumentation. This not only simplifies installation but also reduces overall system complexity and maintenance. The meter’s rugged construction and minimal intrusion into the flow stream also help reduce pressure drop and energy loss, making it a highly efficient solution for steam flow measurement.

Learn More: Rosemount 3051SFA Annubar Flow Meter