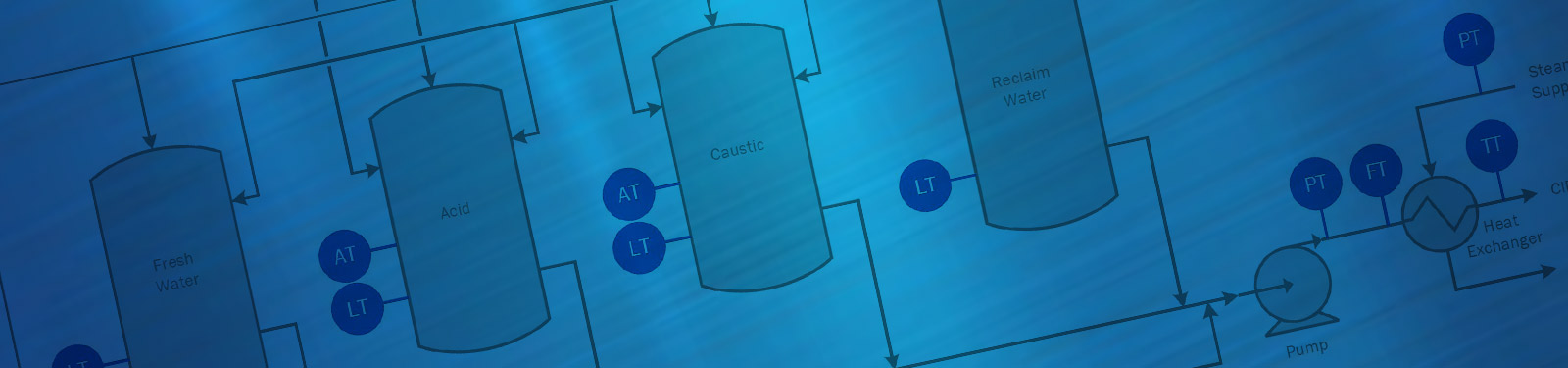

Ensuring the efficacy of CIP processes for a Food and Beverage processing facility requires precise measurement and control.

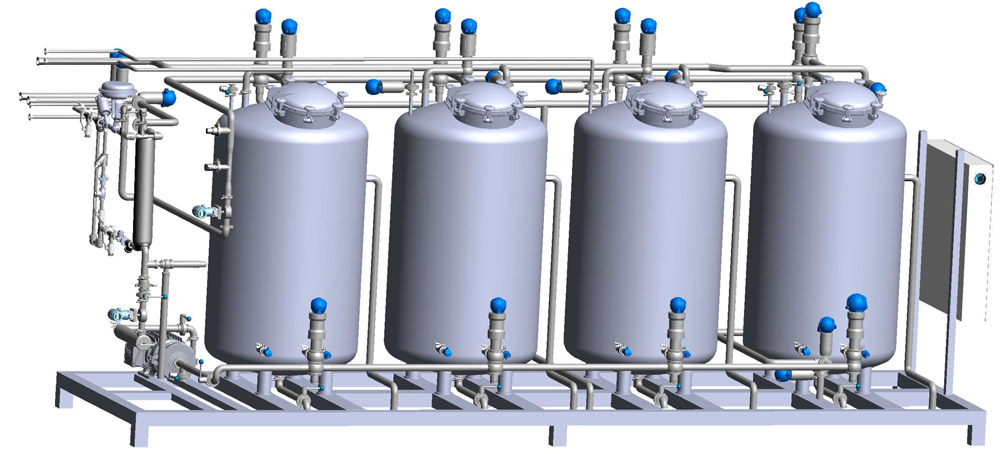

Without the right systems in place, managing the sequencing of lines and vessels for cleaning while optimizing production can be a scheduling challenge. Lakeside Process Controls process equipment and control systems provide a lower-cost, regulatory-compliant solution that increases efficiency, improves safety by reducing cross-contamination, and offers greater assurance of product quality.

Without the right systems in place, managing the sequencing of lines and vessels for cleaning while optimizing production can be a scheduling challenge. Lakeside Process Controls process equipment and control systems provide a lower-cost, regulatory-compliant solution that increases efficiency, improves safety by reducing cross-contamination, and offers greater assurance of product quality.