Romet Natural Gas Rotary Meters

Romet’s robust and reliable energy measurement and monitoring solutions to the natural gas industry are delivered with uncompromising quality and accuracy, while meeting all safety requirements.

Overview

The Romet RM meter is our tried-and-true classic design

This all-aluminum cast meter has stood the test of time, providing users with reliable and accurate measurement for custody transfer. The RM meter provides multiple configuration options: Flange (ANSI and DIN), Nipple (NPT), and Hub (30Lt to 100Lt).

Rugged

All meters are pressure tested up to 4x MAOP to ensure only the toughest meters leave our facility. All RM meters have a 175 MAOP

Responsive

Each meter is individually factory tested and certified for measurement accuracy meeting or exceeding ANSI B109.3 rotary gas meter requirements.Reliable

Pinned metal timing gears ensure the impellers are continuously synchronized to maintain the highest level of accuracy throughout the meter's lifespan.

Flange Configuration

The flange configuration provides a flat face (FF) flange metering solution for a variety of pipe dimensions.

- ANSI or DIN flange options available

- Flange configuration is available for the entire size range of RM rotary meters:

- RM600 to RM56000 (imperial)

- RM16 to RM1600 (soft metric)

- G10 to G1000 (hard metric)

- Available flange dimensions

- 2", 3", 4", 6", 8"

- DN40, DN80, DN100, DN150, DN200

Nipple Configuration

The nipple configuration provides a 1.5" NPT connection. This configuration is available for specific meter sizes.

- 1.5" NPT connection available for specific meter sizes:

- RM600, RM1000, RM1500 (imperial)

- RM16, RM30, RM40 (soft metric)

- G10, G16, G25 (hard metric)

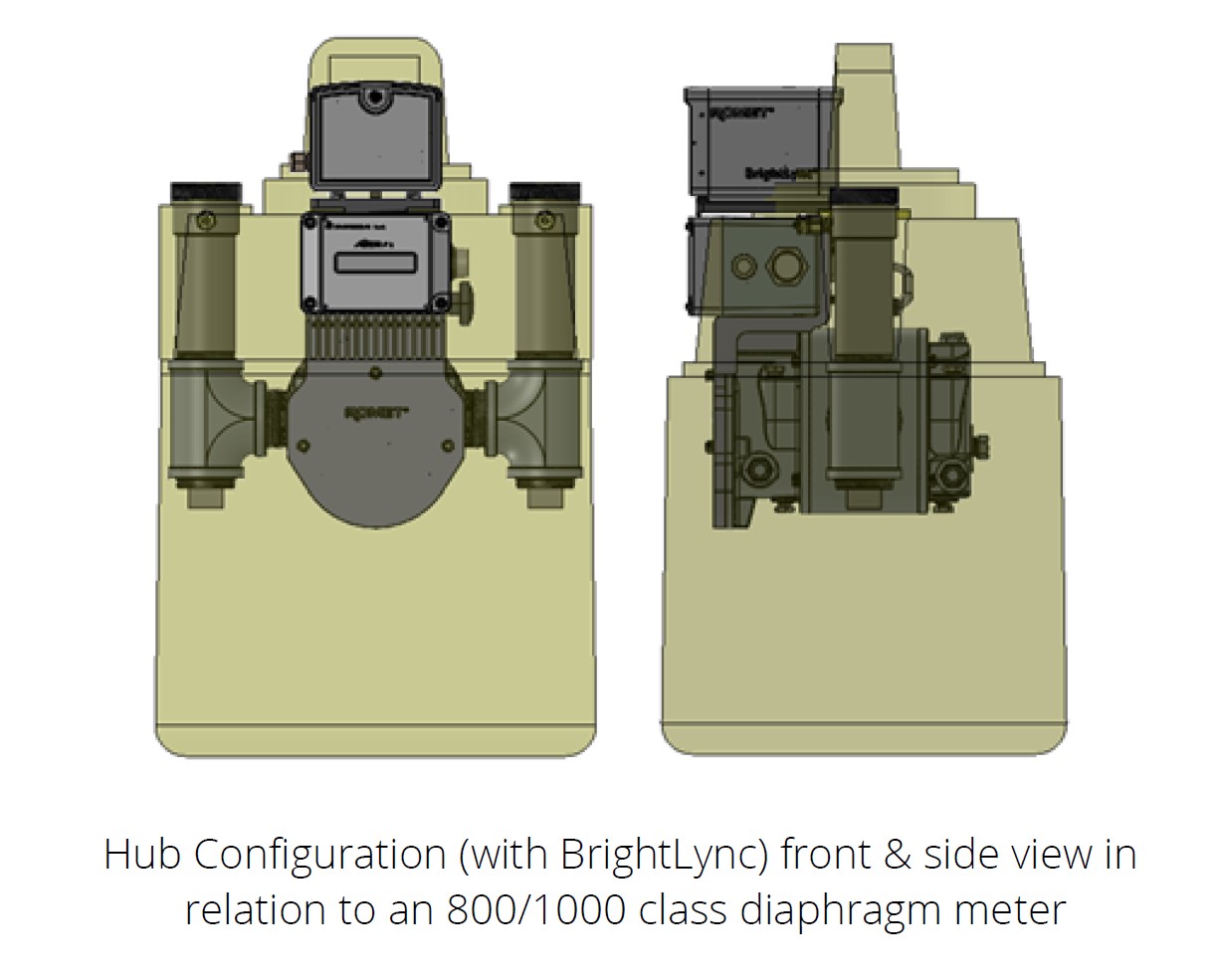

Hub Configuration

The Hub Configuration is designed to fit any application where an eleven inch (11") centre-to-centre hub connection meter would be utilized (800/1000 class diaphragm, ultrasonic, enclosed rotary cartridge).

- 11" centre-to-centre hub connection is available for specific meter sizes:

- RM600, RM1000, RM1500 (imperial)

- RM16, RM30, RM40 (Soft Metric)

- The Hub Configuration provides integrated AdEM® Electronics

- Serial communications

- 4 available pulse outputs

- Full audit trail data log

- BrightLync® compatibility

- Built-in debris sump

- Inlet and outlet pressure plugs

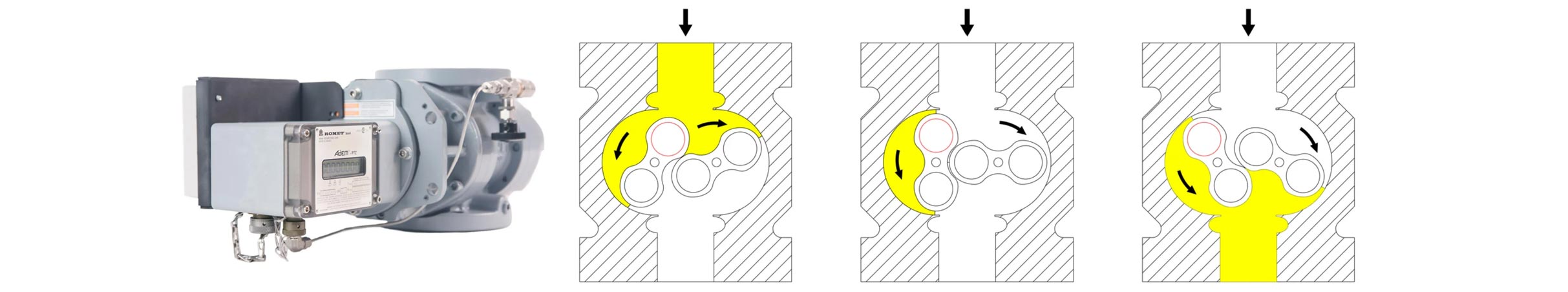

Principles of Operation

Romet measurement devices utilize positive displacement rotary technology. Rotary technology relies on the rotation of two figure eight shaped impellers to perform the measurement operation. These impellers have shafts held in low friction bearings and positioned 90 degrees in relation to each other by precision timing gears. The impellers contra rotate in semi cylindrical housings enclosed by head plates at either end. Very close tolerances and timing gears insure that an effective capillary seal is achieved, at the same time insuring that the impellers and housing do not come in contact.

As gas enters the inlet of the meter, a pressure differential is created from the inlet and outlet of the meter, causing the impellers to rotate. The volume displaced by each revolution of the impellers is transmitted to a final module readout to begin collecting and organizing the generated data.

Where are Rotary Meters Used?

Target Applications

- Natural Gas Totalization: Rotary meters are designed to accurately measure natural gas consumption, making them ideal for applications that require precise totalization data.

- Submetering: Rotary meters are suitable for submetering applications in various industries and businesses, enabling monitoring of efficiency goals, billing purposes, and helping achieve ESG (Environmental, Social, and Governance) objectives.

- Replacing Large Diaphragm Meters: RM body style rotary meters can be used to replace large diaphragm meters commonly found in the industry, which often suffer from leakage problems and long lead times for replacements. Rotary meters offer a more reliable and accurate alternative.

- Remote Areas: The electronic unit of rotary meters operates on batteries and does not require wiring, making them suitable for installations in remote locations where power supply may be scarce or unavailable.

Rotary HUB Meter vs Traditional Diaphragm Meter

The Romet Hub Configuration is designed to fit any application where an eleven inch (11") centre-to-centre hub connection meter would be utilized (800/1000 class diaphragm, ultrasonic enclosed rotary cartridge). The Romet Hub Configuration leverages the robust and accurate measurement capabilities of Romet's trusted and proven rotary meter technology.The Hub Configuration provides advanced measurement and compensation capabilities through integrated Adem Advanced Electronics. This configuration is offered with an integrated Adem-T or Adem-PTZ, providing live gas volume compensation.

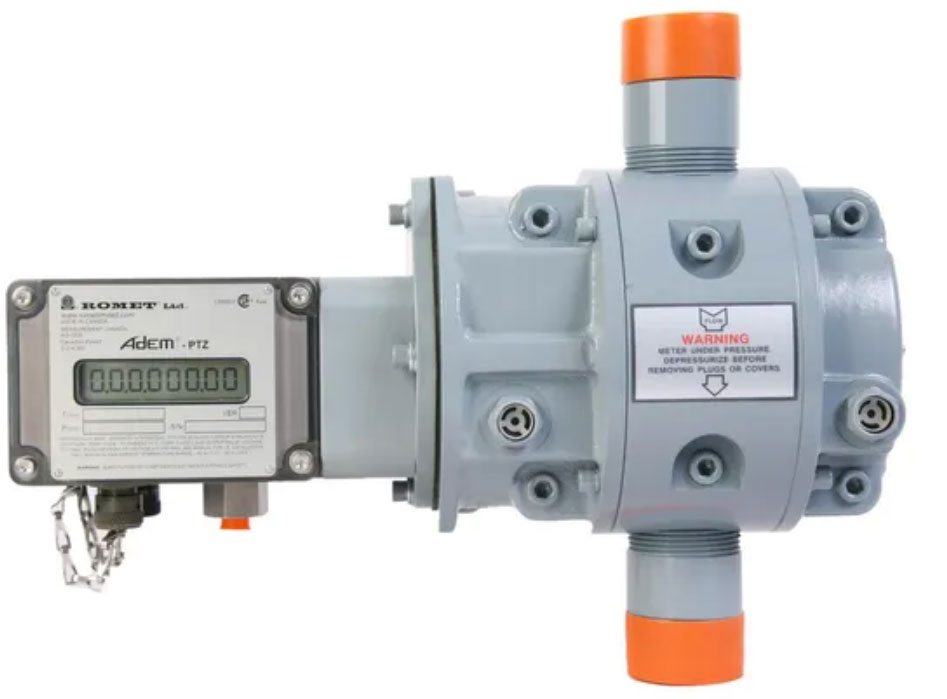

AdEM Module

The Advanced Electronic Module (AdEM®) is a revolutionary electronic solution that replaces traditional "read-only" meters. Unlike mechanical meters, the AdEM® operates without any moving parts or physical contact with a gear system. Instead, it utilizes a Wiegand-effect sensor to convert impeller displacements into pulse inputs for the module. This design ensures enhanced reliability, durability, and accuracy, with reduced maintenance and replacement costs.

The AdEM-T version offers temperature compensation, accounting for temperature changes to provide accurate readings. On the other hand, the AdEM-PTZ variant includes pressure and temperature compensation, enabling precise gas flow measurements even under varying operating conditions. These compensation features are especially valuable for accurate billing and precise gas consumption measurement.

The AdEM® represents a significant advancement in natural gas metering technology, with its non-contact electronic design and optional compensation features. It delivers reliable and accurate measurements while reducing maintenance needs, making it a valuable choice for various applications.

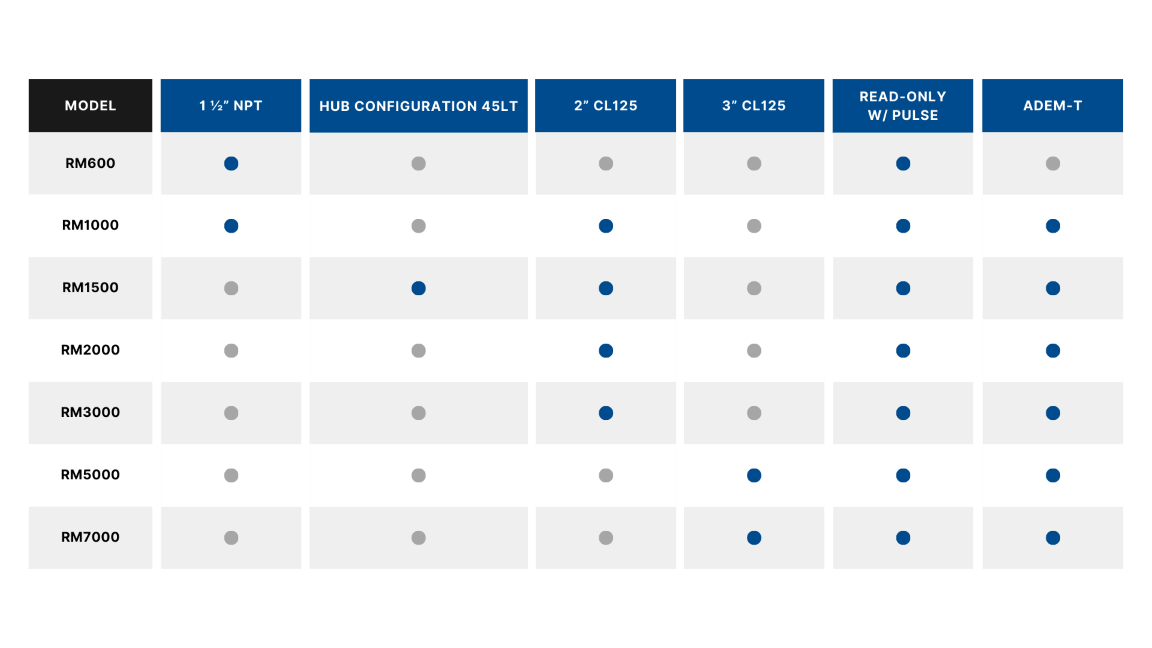

Inventory at Lakeside

Our inventory includes various threaded options, HUB configuration options, and 2" / 3" flanged meters. This provides flexibility with various installation requirements. Additionally, all our meters are paired with the AdEM-T module, which incorporates temperature compensation for accurate measurements even in the presence of temperature variations. By offering this comprehensive range of options, we aim to meet the diverse needs of our valued customers.